Spraying operation of glass candlestick

Perhaps we are familiar with the glass candle holder in our daily life, especially when we use it many times, but the quality of the glass candle holder will directly affect our use.Sunny glassware Focusing on luxury fragrance products in the latest 10 years, Sunny Glassware is the supplier of 80% fragrance brands in the United States.So, in the operation of glass spraying, how many steps need to be carried out? Sunny Glassware will take you to understand today:

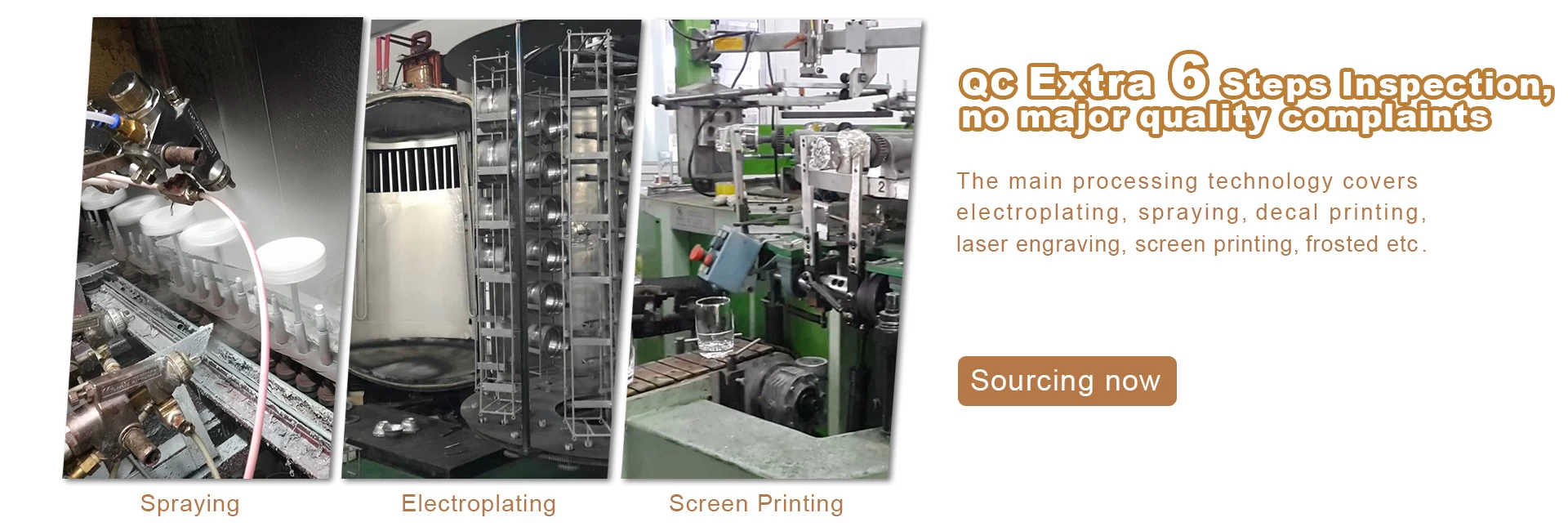

Pretreatment section: glass bottle spraying pretreatment section includes pre-stripping, main stripping, surface adjustment, etc., if in the north, the temperature of the main stripping part should not be too low, insulation is necessary. Otherwise, the treatment effect of glass candlestick is not ideal.

Preheating section: After pretreatment, it will enter the preheating section, which usually takes 8 ~ 10 minutes. When the glass bottle reaches the dusting room, the sprayed workpiece must have a certain amount of residual heat to increase the adhesion of the bottle body and powder.

Glass candlestick ash blowing purification section: if the process requirements of the sprayed workpiece are relatively high, this section is indispensable, otherwise if the dust on the workpiece is a lot, the processed surface will have a lot of granular, will reduce the quality.

Dusting link: This link is the most important dusting master's technical problems.

Glass bottle custom drying section: this section should pay attention to the temperature and baking time. Powder is usually 180 to 200 degrees Celsius. It depends on the material of the workpiece. The drying furnace should not be too far away from the powder spraying room, generally 6 meters is appropriate.

Glass is also a material with a long history. The glass is non-toxic, tasteless, transparent, beautiful, good barrier, airtight, rich in raw materials, universal, low price. , and can be used for scented candles and other repeated use, and has the advantages of heat resistance, pressure resistance, cleaning resistance. High temperature disinfection, low temperature storage. It is because of its many advantages that make it the first choice among candlesticks.

With a variety of materials flooding into the market, glass materials still occupy an important position in the glass candlestick. Plastic bottles have always relied on the labeling process to improve the outer packaging of products, from the appearance of the bottle body. In contrast, glass candlesticks have a variety of options in the late modification process, including paint, spray paint, scrub and other effects, making glass candlesticks often become a variety of different visual effects.